Zhenheng 40 M3/H Diesel Concrete Mixer Pump With Drum Mixer Combination

Product Description

Concrete mixer with pump is a kind of concrete pouring equipment integrating feeding, mixing and pumping. It is widely used in road construction, building construction, tunnel construction, bridge construction, slope protection construction, etc. With the development of urban construction, concrete mixing pumps are becoming more and more popular.

According to the driven engine, our concrete mixer with pump for sale includes diesel engine and electrical motor. If your area is lack of electricity, the diesel engine concrete mixer machine with pump is suitable for sale. On the contrary, you can buy the electric motor concrete mixer pump.

Features:

1). Adopt Open hydraulic system, which is with stable and reliable performance, low failure rate.

2). Integration control for mixing and pumping, wireless remote control which makes operation convenient.

3). Adopt wear-resistant alloy materials for the concrete mixer, prolong the service life.

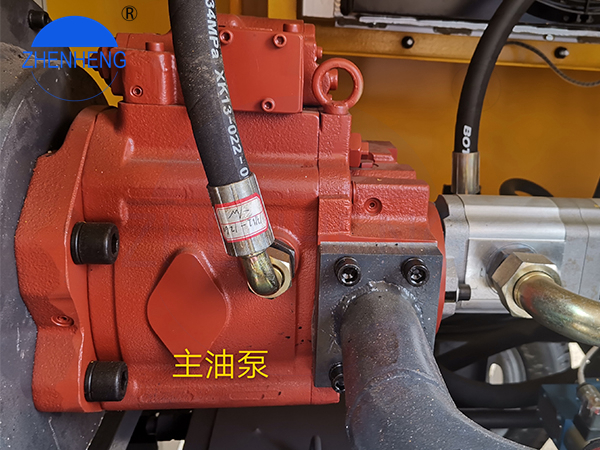

4). Main oil pump. Adopt domestic famous brand Kawasaki series.

5). Lubrication system. Adopt automatic lubrication system, high oil pressure with stable lubrication effect.

6). Power system. Adopt domestic and world famous motor or diesel engine.

7). Control system. Adopt Japan Omron PLC control system, equipped with wireless remote control, makes the operation more flexible and convenient.

8). S valve. Wear-resistant cast iron materials, enjoys the advantages of anti-high pressure and anti-wearing.

9). Concrete piston. Precisely processed by imported material, enjoys the features of hydrulytic resistant, wear resistant and high temperature resistant.

Details:

1. Hydraulic Oil Pump

Kawasaki Hydraulic pump is one of the most important parts of concrete pump, it generates hydraulic pressure to deliver concrete to the job site.

2. Diesel Engine

1) Chinese famous brand diesel engine, strong power, fuel saving

2) can be customized according to client's requirements, for example: Cummins, Deutz, Yuchai, etc.

2. Diesel Engine

1) Chinese famous brand diesel engine, strong power, fuel saving

2) can be customized according to client's requirements, for example: Cummins, Deutz, Yuchai, etc.

3. Control System

1) equipped with remote controller, simple operation.

2) When the proximity switch fails, it can work normally when the switch is turned on, without wasting concrete and reducing the trouble of manual cleaning of pipes.

3) PLC, Omran.

4. Delivery Pipe and Acessories

1) 100meter pipe is included with the concrete mixer pump machine

2) At the end of pumping, the pump machine and delivery pipe should be cleaned in time.

The cleaning of the concrete delivery pipe is mostly washed with water, and the sponge ball is inserted from the feed port so that there is no gap between the sponge ball and the concrete mixture, so as to prevent the pressure water from passing through the sponge ball concrete mixture.

4. Delivery Pipe and Acessories

1) 100meter pipe is included with the concrete mixer pump machine

2) At the end of pumping, the pump machine and delivery pipe should be cleaned in time.

The cleaning of the concrete delivery pipe is mostly washed with water, and the sponge ball is inserted from the feed port so that there is no gap between the sponge ball and the concrete mixture, so as to prevent the pressure water from passing through the sponge ball concrete mixture.

5. Constant Pressure Pump

Provide power to the stirring shaft and the mixer separately, and cool the oil pump, so that the oil temperature of the equipment system will not be too high, causing the plunger pump to leak, and increasing the service life of the equipment.

Parameters

|

Model |

JBS40-10-84R |

|

Productivity |

40m3/hr |

|

Pumping Pressure |

10Mpa |

|

Outlet Diameter |

Φ150mm |

|

Delivery Distance(Vertical/Horizontal) |

70/300m |

|

Max Aggregate Diameter |

40mm |

|

Inside diameter of delivering pipe |

Φ125mm |

|

Pipe |

100m |

|

Power |

84kw |