Ready Mix Batch Mixing Plant Drum Mobile Concrete Plants For Sale in Philippines

Product Description

Drum Mixer Mobile Batching Plant is one type of mobile concrete production plants that equipped with drum concrete mixer with aggregate dosing machine in a frame. It is an economical mobile concrete of production equipment, commonly used in buildings, bridges, dams and roads construction. The mobile batching plant using the drum mixer is under a simple structure,which is cheaper and more energy-efficient, and it is suitable for the production of low-grade concrete. We recommend it in small projects.

Applications:

1. Railways

High degree of automation and high production efficiency, making production and processing easy and efficient.

2. Highway

High mixing quality and short cycle time. It is an indispensable mechanical equipment in road construction.

3. Bridge construction

The triple superiority makes it irreplaceable in bridge construction.

4. Water conservancy construction

Convenient operation and smooth running make water conservancy construction more convenient.

5. Port and dock facilities

Forming a simple mixing plant makes port and dock construction easier.

Details:

1. JZM Concrete Mixer

Adopting the JZM concrete mixer. It can mix by rotating conversely and discharge by rotating reversely. Low noise, low power consumption, no pollution.

2. Metering System

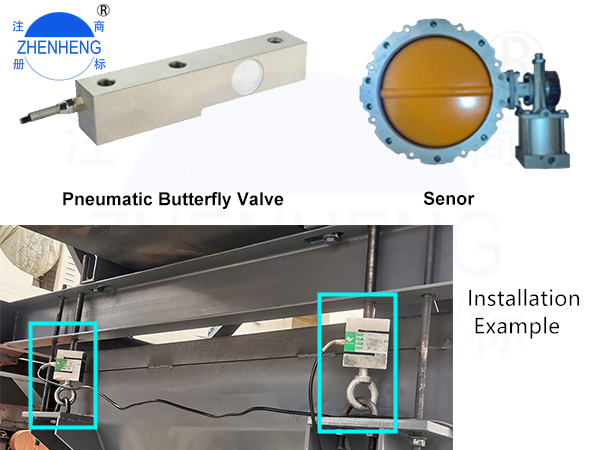

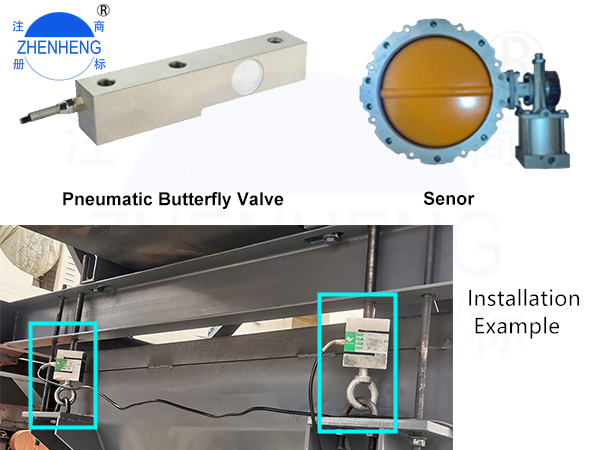

1) The sensor adopts high-precision imported sensor, accurate weighing and quick response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight and high in cost performance.

2. Metering System

1) The sensor adopts high-precision imported sensor, accurate weighing and quick response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight and high in cost performance.

3. Small Cement Hopper

The cement powder in 50kg/100kg type or jumbo bag type can be transferred to mixer through cement hopper and screw conveyor. There is a blade inside the cement hopper, which can damage the bag, drop the material into the bottom, and send it to the mixer by screw conveyor.

4. Tires & Universal Steering Wheel

1) Double tires, strong pressure bearing capacity, strong stability, non-slip

4. Tires & Universal Steering Wheel

1. Double tires, strong pressure bearing capacity, strong stability, non-slip

Parameters

|

Model |

YHZM100 |

|

Productivity |

100m3/hr |

|

Mixer Type |

JZM2000 |

|

Discharge Volume |

2000L |

|

Aggregate Batch Machine |

10m3 * 3bins |

|

Maximum Aggregate Size |

60/80mm |

|

Unloading Height |

1.8m |

|

Screw Conveyor |

LSY273*9m |

|

Weighing Accuracy |

±1% |

|

Control System |

Fully Auto |

|

Cement Silo |

70T |