Precast Hollow Core Concrete Floor Slab Make Machine Precast Concrete Slab Pushing Machine Concrete Slab Mold

Product Description:

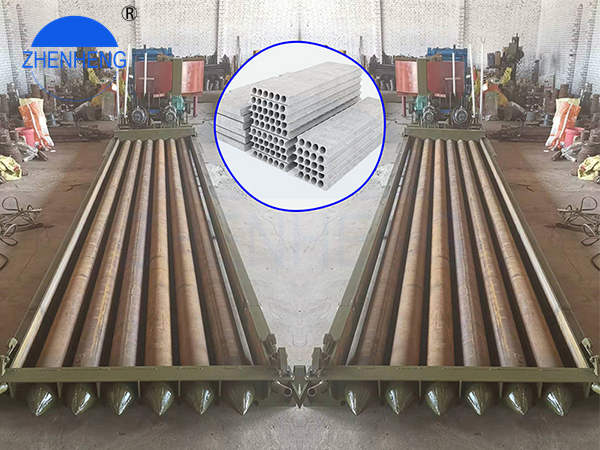

Floor extrusion molding machine is a new type of prefabricated component production machinery. It is suitable for extrusion forming of various prestressed concrete circular orifice plates for industrial and civil buildings. This mechanical technology is widely used in the forming of various prestressed concrete round-hole prefabricated panels in urban and civil buildings. It adopts automatic walking, continuous operation, and one-time forming. Compared with traditional manual forming methods (molding, rapid demoulding) , not only uniform reinforcement, high strength of plate making, fast speed (1.2-1.4 m/min), good quality, but also labor-saving, time-saving, material-saving, cement 30-50kg, and labor intensity reduced. It is an ideal board making equipment for the prefabrication industry.

Features:

• Lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Simple structure, easy operate, less wear parts

Details:

1. Improve Productivity

The concrete hollow core slab machine adopts a modular cast-iron girder to ensure the stability and service life of the whole machine

The hollow core slab machine is equipped with a medium frequency (100HZ ) vibrator as the vibrating source. The production efficiency of the machine will be improved greatly, and the slab's finishes will be better. Meanwhile, the materials of concrete can be saved about 50Kg per ton comparing with traditional design.

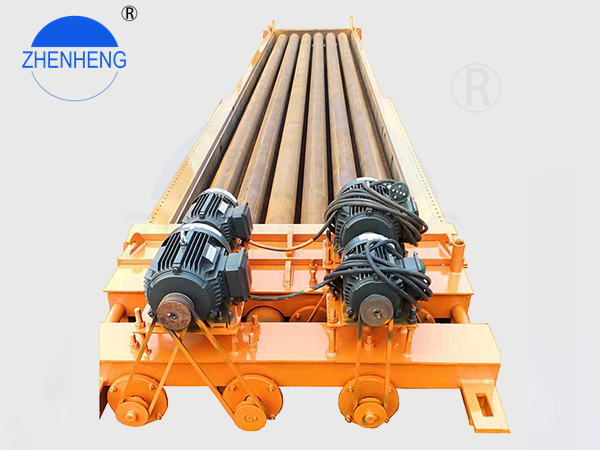

2. Electric Motors & Vibrators

Low energy consumption. The machine is only equipped with one main motor and one vibrator.

The key spare parts of the machine are made of highly wear-resistant materials. Thanks to this, the machine has a long service life. For customers, it will save maintenance costs and reducing operating costs to drive more value.

2. Electric Motors & Vibrators

Low energy consumption. The machine is only equipped with one main motor and one vibrator.

The key spare parts of the machine are made of highly wear-resistant materials. Thanks to this, the machine has a long service life. For customers, it will save maintenance costs and reducing operating costs to drive more value.

3. Finished Concrete Slabs

The quality of the finished product is excellent. Due to the unique machinery design, strict manufacturing standards, the slabs products produced can widely meet the technical and construction requirements.

4. Low Labor Intensity

Only 3-5 peoples are required to complete the entire production process. The machine is small in size and light in weight, which is convenient for movement and transportation when the production site is changed.

4. Low Labor Intensity

Only 3-5 peoples are required to complete the entire production process. The machine is small in size and light in weight, which is convenient for movement and transportation when the production site is changed.

Parameters

|

Model |

MP750 |

MP1000 |

MP1250 |

MP1500 |

MP2000 |

MP2500 |

MP3000 |

MP4000 |

|

Out Capacity |

750L |

1000L |

1250L |

1500L |

2000L |

2500L |

3000L |

4000L |

|

Input Capacity |

1125L |

1500L |

1875L |

2250L |

3000L |

3750L |

4500L |

6000L |

|

Out Weight |

1800kg |

2400kg |

3000kg |

3600kg |

4800kg |

6000kg |

7200kg |

9600kg |

|

Mixing Power |

30kw |

37kw |

45kw |

55kw |

75kw |

90kw |

110kw |

160kw |

|

Discharging Power |

2.2kw |

3kw |

3kw |

3kw |

4kw |

4kw |

4kw |

4kw |

|

Weight |

3500kg |

5800kg |

6500kg |

7600kg |

8500kg |

10500kg |

11000kg |

16800kg |

|

Dimension |

2581*2336*2195 |

2981*2602*2217 |

2891*2602*2217 |

3223*2902*2425 |

3625*3230*2630 |

2893*3550*2695 |

3893*3550*2975 |

4562*4150*3105 |