Mobile Small Electric Beton Machine Portable Pump Concrete Mixer And Pump With Concrete Pump And Mixer In Philippines

Product Description

Concrete mixer with pump is a kind of concrete pouring equipment integrating feeding, mixing and pumping. It is widely used in road construction, building construction, tunnel construction, bridge construction, slope protection construction, etc. With the development of urban construction, concrete mixing pumps are becoming more and more popular.

Due to stable performance and high pumping efficiency, Zhenheng mixing pumps have been exported to the Philippines, Pakistan, Indonesia, Egypt, Thailand, South Africa, Malaysia and other countries and regions, with strong adaptability. It works well even in tight areas.

Features:

1). Use double pumps, two-circuits open hydraulic system, oil circuit of the master pump and swing oil circuit of S distributing valve are independent, which makes the system easy, prolongs the lifespan of elements, the reliability is higher than before, and is convenient to judge and exclude the fault;

2). The reverse state is beneficial to eliminate fault of tube plugging and can stop functioning and wait for the materials for a short time. It is also good for prolonging the service life of the pump machine;

3). Use advanced S distributing valve, can automatically make up for wearing clearance and the seal performance is good;

4). Use wear-resistant alloy glasses board and float glass cutting, life service is long;

5). An automatic and intensive lubrication system ensures effective lubrication during the operation;

6). The remote control makes the operation safer and more convenient;

7). All the spare parts meet the national standard, and interchangeability is much better;

8). The cooling system uses a forced air cooling radiator device to ensure the working oil temperature, under 70 centigrade, and guarantee the main engine hydraulic system is in normal working condition.

Details:

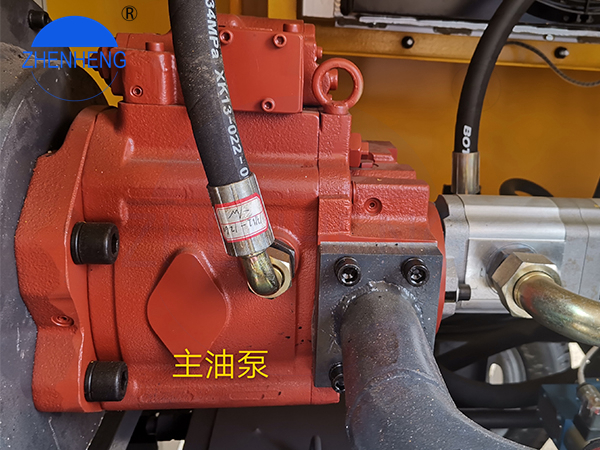

1. Hydraulic Oil Pump

Kawasaki Hydraulic pump is one of the most important parts of concrete pump, it generates hydraulic pressure to deliver concrete to the job site.

2. Mixing System

A special S-tube spline shaft protection device is designed to reduce the frequency of replacing the S-tube and reduce maintenance costs.

2. Mixing System

A special S-tube spline shaft protection device is designed to reduce the frequency of replacing the S-tube and reduce maintenance costs.

3. Control System

1) equipped with remote controller, simple operation.

2) When the proximity switch fails, it can work normally when the switch is turned on, without wasting concrete and reducing the trouble of manual cleaning of pipes.

3) PLC, Omran.

4. Delivery Pipe and Acessories

1) 100meter pipe is included with the concrete mixer pump machine

2) At the end of pumping, the pump machine and delivery pipe should be cleaned in time.

The cleaning of the concrete delivery pipe is mostly washed with water, and the sponge ball is inserted from the feed port so that there is no gap between the sponge ball and the concrete mixture, so as to prevent the pressure water from passing through the sponge ball concrete mixture.

4. Delivery Pipe and Acessories

1) 100meter pipe is included with the concrete mixer pump machine

2) At the end of pumping, the pump machine and delivery pipe should be cleaned in time.

The cleaning of the concrete delivery pipe is mostly washed with water, and the sponge ball is inserted from the feed port so that there is no gap between the sponge ball and the concrete mixture, so as to prevent the pressure water from passing through the sponge ball concrete mixture.

5. Constant Pressure Pump

Provide power to the stirring shaft and the mixer separately, and cool the oil pump, so that the oil temperature of the equipment system will not be too high, causing the plunger pump to leak, and increasing the service life of the equipment.

Parameters

|

Model |

JBS30-10-37 |

JBS40-13-45 |

|

Productivity |

25m3/hr |

35m3/hr |

|

Pumping Pressure |

10Mpa |

13Mpa |

|

Outlet Diameter |

Φ100mm |

Φ150mm |

|

Delivery Distance(Vertical/Horizontal) |

70/300m |

70/300m |

|

Max Aggregate Diameter |

20mm |

40mm |

|

Inside diameter of delivering pipe |

Φ100mm |

Φ125mm |

|

Pipe |

100m |

100m |

|

Power |

37kw |

45kw |