Mini 2m3 3m3 4m3 5m3 6m3 7m3 8m3 9m3 10m3 12 M3 Concrete TRANSIT MIXER DRUM HOIST 8Cubic Mezcladora De Cemento concreto for sale

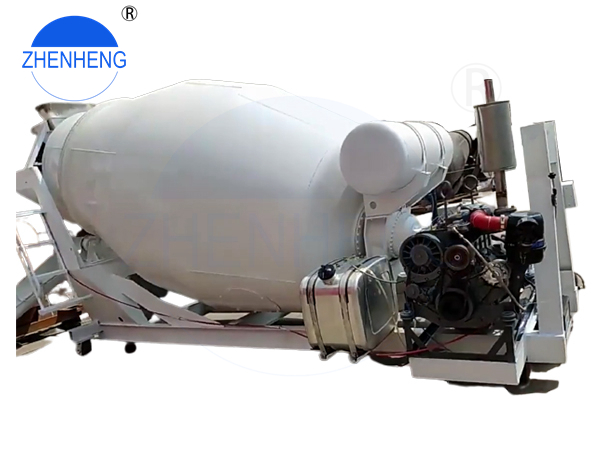

Product Description

The mixer drum is either driven by the truck engine or by a separate power take off device.

It mixes material by itself or be mounted on truck to use as a concrete mixer truck.When the concrete drum rotates clockwise, the concrete is stirred, and when it is rotated counterclockwise, the concrete is discharged.

The whole mixing system of Concrete mixer drum includes mixing tank and bearings, out of the hopper, hydraulic system and reducer, water tanks and pipelines, operating linkage agencies.

Features:

1). The use of iron and steel production of special wear-resistant plate mixing drum and blade.

2). Mixing drum blade production process using special mold stamping.

3). Drum and blade welding adopts large rotary tooling, high precision.

4). The hydraulic system adopts imported components, compact structure and excellent performance.

5). The whole mixing.drum styling chic, beautiful, compact and reasonable structure.

6). The operating system is flexible and convenient, the realization of the left and right, feed operation three in one.

7).The pot body after welding adopts blast pretreatment process, to achieve derusting and rust.

Details:

1. Equipped with Diesel Engine

Equipped with diesel engine or electric motor as customer's request. so that it can be used alone as a concrete mixer.

2. Replace The Old Mixer Drum

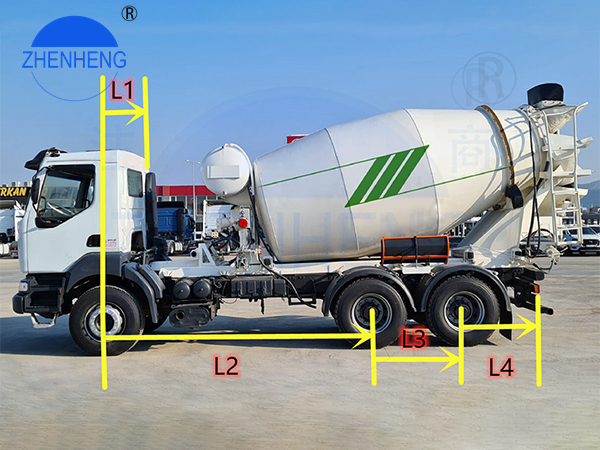

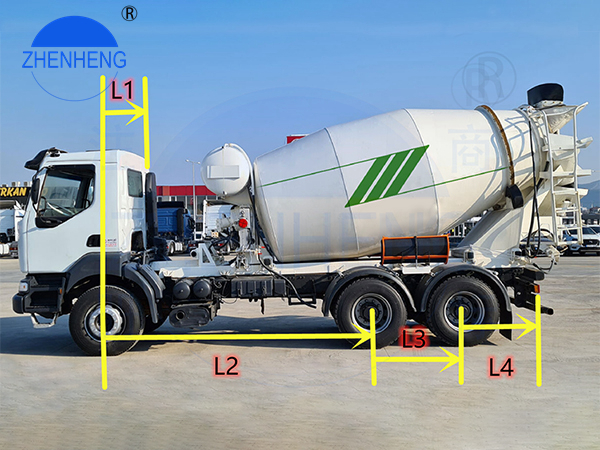

If you want to purchase a new mixer drum mounted on the truck, just check some dimensions as photo shows and other details, we will design a suitable drum mixer for your truck.

2. Replace The Old Mixer Drum

If you want to purchase a new mixer drum mounted on the truck, just check some dimensions as photo shows and other details, we will design a suitable drum mixer for your truck.

3. Drum Tank and Accessories

1) Hydraulic system: famous brand Sunny, the structure is simple and reliable.

2) Water supply system: It supplies water by pressure, which saves the labor intensity and reduces the car weight.

3) Mixing drum: It is pear shaped and has dual helical blades, which improves the concrete quality; The installing angle of the drum is small, which reduces the vehicle center of gravity and is conducive to the clean discharge of the concrete.

4) Control device: It can be divided into soft shaft manipulator and link manipulator, which can achieve the multiple points charging and discharging control; the charging hopper and discharging chute can rotate 180 degree in the horizontal direction to adapt to different position.

Parameters

Item |

4m3 |

5m³ |

6m3 |

7m3 |

8m3 |

10m3 |

12m3 |

Delivery capacity of mixing drum |

4m³ |

5m³ |

6m³ |

7m³ |

8m³ |

10m³ |

12m³ |

Geometrical capacity of mixing drum |

6.1m³ |

8.5m³ |

9.6m³ |

10.2m³ |

11.8m³ |

15m³ |

18.7m³ |

The axis inclination angle |

15° |

15° |

15° |

15° |

15° |

14° |

11° |

The charging speed |

≧3m³/min |

≧3m³/min |

≧3m³/min |

≧3m³/min |

≧3m³/min |

≧3m³/min |

≧3m³/min |

The discharging speed |

≧2m³/min |

≧2m³/min |

≧2m³/min |

≧2m³/min |

≧2m³/min |

≧2m³/min |

≧2m³/min |

The discharging residual rate |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

Drum material |

Q345B |

Q345B |

Q345B |

Q345B |

Q345B |

Q345B |

Q345B |

Drum thickness |

4mm |

5mm |

5mm |

5mm |

5mm |

5mm |

5mm |

Drum diameter |

1750mm |

2050mm |

2050mm |

2150mm |

2200mm |

2200mm |

2400mm |

Weight |

1445kg |

2060kg |

2260kg |

2420kg |

3400kg |

3800kg |

4100kg |

Reducer |

Keyi |

Keyi |

Keyi |

Keyi |

PMP |

PMP |

PMP |

Hydraulic motor |

BMS30-125 |

BMT50-250 |

BMT50-250 |

BMT50-250 |

Sunny |

Sunny |

Sunny |

Radiator |

16L |

18L |

18L |

18L |

18L |

18L |

18L |

water supply |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

Pneumatic |

water tank |

200L |

200L |

350L |

350L |

400L |

350L |

400L |