China Factory Price YHZS25 Twin Shaft Concrete Batching Plant Mobile Concrete Mixer Equipment

Product Description

Mobile concrete mixing plant which adopts advanced technologies and scientific researching results from home and abroad and combines our company’s years’ mixing station producing experience, which is a new type mobile concrete mixing station designed by our company independently .It is now one of the best mixers in China, which boasts compact and reasonable designing. Most functions of the mixing station are finished in the pulling chassis, combining aggregate, electronic weighing, mixing and lifting together.It can be stopped to run or be pulled away easily, which is convenient to move and easy to install.

Features:

1. Adopting module structure, designed as per the loading of container standard. All modules are in one trailing unit. Easy for installation and disassembly. Fast for moving.

2. Main mixing unit is JS500 double-shaft, forced concrete mixing mixer, with good mixing quality, high production efficiency. Perfect mixing can be done within ideal time period for dry-hard, half-dry-hard, plastic and concrete with any mixing ratio.

3. All scaling elements and control elements of scaling unit are imported elements and controlled by computer, guaranteeing completely accurate scale and stable function.

4. Platform or ladder is equipped to each part needing maintenance and repairing. Good for maintenance.

5. The whole system adopts complete automatic system via computer, with dynamic panel display, to show clearly of the running of each part. Visualized monitor interface provides clear and accurate observing to the site working procedure. Table or list can be print out.

6. Electrical control system adopts import elements, providing a stable and powerful function. Automatic test for the abnormal working condition, Word, sound, light alarm, easy and good for the maintenance and trouble shooting.

Details:

1. JS Concrete Mixer

JS500 double horizontal shaft forced-type concrete mixer, can mix liquid , dry hard, lightweight aggregate concrete and various types of concrete. The mixer has reasonable structure, good mixing quality, short stirring time, energy saving and low noise.

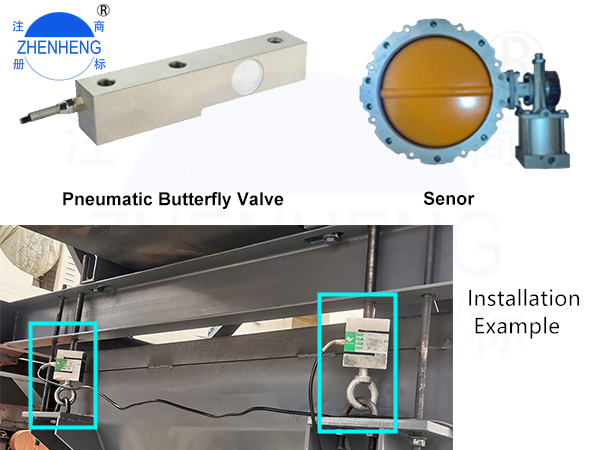

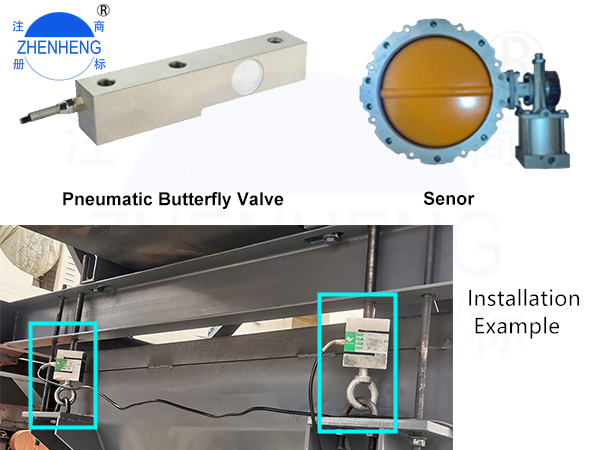

2. Metering System

1) The sensor adopts high-precision imported sensor, accurate weighing and quick response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight and high in cost performance.

2. Metering System

1) The sensor adopts high-precision imported sensor, accurate weighing and quick response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight and high in cost performance.

3. Small Cement Hopper

The cement powder in 50kg/100kg type or jumbo bag type can be transferred to mixer through cement hopper and screw conveyor. There is a blade inside the cement hopper, which can damage the bag, drop the material into the bottom, and send it to the mixer by screw conveyor.

4. Belt Conveyor

1) High feeding and transportation efficiency

2) Improve production efficiency by more than 20%

4. Belt Conveyor

1) High feeding and transportation efficiency

2) Improve production efficiency by more than 20%

5. Fully Auto Control System

1) Self-developed dual-computer synchronous production management and control system, plus the patent of fault warning, multiple guarantees to make your equipment never stop;

2) Reports are automatically classified and summarized, and cloud data storage ensures clear data and convenient operation.

Parameters

|

Model |

YHZS25 |

|

Productivity |

25m3/hr |

|

Mixer Type |

JS500 |

|

Discharge Volume |

500L |

|

Aggregate Batch Machine |

4m3 * (2-3bins) |

|

Unloading Height |

3.8m |

|

Weighing Accuracy |

±1% |

|

Weighing System |

water, cement, additive |

|

Power |

50kw |

|

Control System |

Fully Auto |

|

Cement Silo |

50T |

|

Screw Conveyor |

LSY219*8m |