Bolted Vertical Pieces Cement Powder Storage Steel Silos For Concrete Batching Plant

Product Description

Features:

1) Easy to transport, assemble and disassemble.

2) Short construction period and low cost. On-site construction, fast installation. The silo is made of thin steel plate, the weight is greatly reduced, and then reduce the cost and freight.

3) Good air tightness and wide application. We adopt the special equipment for rolling silo, which is used to bend and bite to ensure the process quality of any cement silo parts. So. the silo is well sealed, which can prevent moisture and penetration.

Details:

1. Dust Collector

The top of the cement silo is equipped with a dust removal device (electric or pulse), which can effectively absorb the suspended particles in the silo and reduce the pollution to the surrounding environment.

2. Butterfly Valve

1) The sensor adopts high-precision imported sensor, accurate weighing and quick response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight and high in cost performance.

2. Butterfly Valve

1) The sensor adopts high-precision imported sensor, accurate weighing and quick response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight and high in cost performance.

3. Level Gauge

The cement silo material level device can sense the storage height of the material in the silo.

4. Arch Breaking Device

The lower cone of the cement silo is equipped with an air blowing arch breaking device, which uses a small electromagnetic reversing valve in the air control box to control the release of compressed air to break the arch of cement and various powder materials to avoid powder accumulation and blockage.

4. Arch Breaking Device

The lower cone of the cement silo is equipped with an air blowing arch breaking device, which uses a small electromagnetic reversing valve in the air control box to control the release of compressed air to break the arch of cement and various powder materials to avoid powder accumulation and blockage.

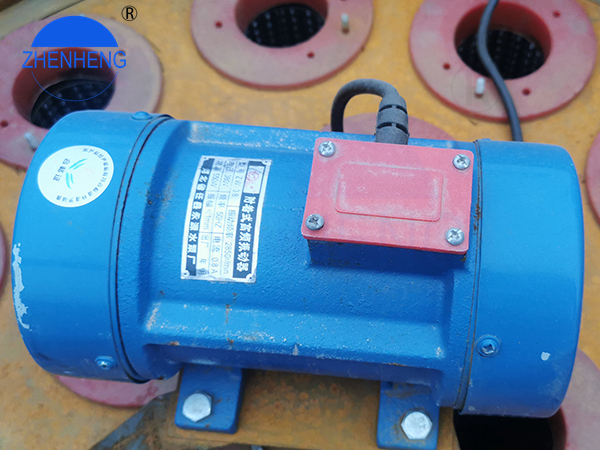

5. Vibrator

The cement powder in 50kg/100kg type or jumbo bag type can be transferred to mixer through cement hopper and screw conveyor. There is a blade inside the cement hopper, which can damage the bag, drop the material into the bottom, and send it to the mixer by screw conveyor.

Parameters

|

Bolted Cement Silo |

||||

|

Volume |

Diameter |

Thickness |

Total Height |

Weight |

|

60T |

3200mm |

4/5/6 |

12-18m |

4-6.5t |

|

100T |

32mm |

4/5/6 |

15-18m |

5-8.8t |

|

150T |

3200mm |

4/5/6 |

15-20m |

6-12t |

|

200T |

4500mm |

4/5/6 |

15-20m |

7.5-14t |

|

300T |

5300mm |

4/5/6 |

15-20m |

9-18t |