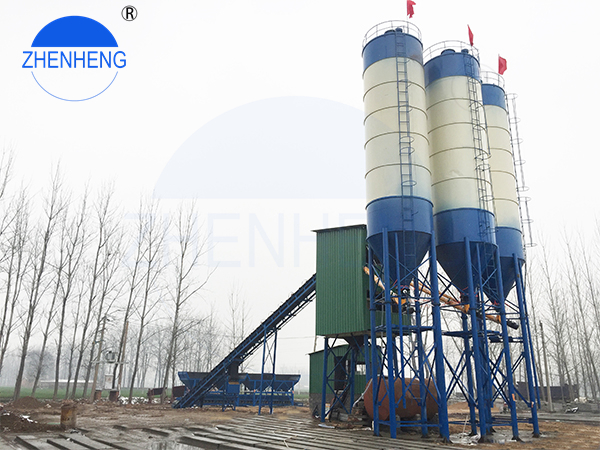

Hzs60 Small Ready Mixed Manufacturer Supplier Concrete Mixing Plant 60M3/H Ready Mix Concrete Batching Plant

Products Description

Stationary concrete batching plant is composed of aggregate batching system, aggregate convey system, batching system, mixing system, electrical control system, water supply system, air supply system, additive supply system, cement conveyor belt and cement silo. It suits to building site and merchandise concrete produce.

Stationary HZS60 concrete mixing plant Because of its mechanization and high degree automation,so the productivity is very high, and to ensure the quality of concrete and save the cement, commonly used in large projects and long duration concrete cement/aggregate usage for the large and medium-sized water conservancy, electricity, bridges and other industrial and civil building engineering.

Features

1. Short production cycle and large discharge volume, it’s suitable for commercial concrete batching plants.

2. The belt type mixing station has high feeding and transportation efficiency.

It can quickly complete large-scale operation requirements, and improve production efficiency by more than 20%.

3. It can continuously provide feeding, and the transmission distance is relatively large, which can well meet the needs of large-scale mixing plants.

Detail

1.Transportation system

1) High feeding and transportation efficiency

2) Improve production efficiency by more than 20%

2.Agitating system

1) High wear-resisting alloy mixing arm has high wear-resisting performance and strong impact resistance.

2) Sealing protection technology does not leak;

3) Mix concrete of all strengths

2.Agitating system

1) High wear-resisting alloy mixing arm has high wear-resisting performance and strong impact resistance.

2) Sealing protection technology does not leak;

3) Mix concrete of all strengths

3. Batching system

1) High precision, fast speed, simple operation, etc.

2) Electronic weighing, microcomputer control, digital display;

3) Remote operation with weighing accuracy.

4. Control system

1) The machine adopts computer control, simple operation, easy to master;

2) Dynamic panel display, can clearly understand the operation of each component, at the same time can store and print data.

4. Control system

1) The machine adopts computer control, simple operation, easy to master;

2) Dynamic panel display, can clearly understand the operation of each component, at the same time can store and print data.

Parameters

|

Model |

HZS60 |

|

Productivity |

60m3/hr |

|

Mixer Type |

JS1000 |

|

Aggregate Number |

4 |

|

Maximum Aggregate Size |

40/60mm |

|

Unloading Height |

4.1m |

|

Aggregate weighing range |

0-2000kg |

|

Cement weighing range |

0-600kg |

|

Water weighing range |

0-300kg |

|

Additive weighing range |

0-30kg |

|

Fly ash weighing range |

0-300kg |

|

Dimension |

38*20*23.1m |

|

Cement Silo |

100T,200T |