35m3/H Mobile Wet Precast Ready Mixed Concrete Plant Yhzs35

Product Description

Mobile concrete mixing station is a trailer unit of concrete production equipment of material storage, and weighing, and conveying, and mixing, and unloading materials and full control system overall concentrated; It has characteristic of mobile flexible, and disassembly quick simple, and store management simple; It suits public railway, and bridge, and port, and hydropower, engineering mobile construction.

Features:

1) YHZS series batching plants are characterized by ultra mobility, artful manufacturing process, and high technology, which are embedded in details, such as improved chassis, hydraulic outriggers, accurate weighing devices, full automation, etc.

2) No foundation is needed, not some days but only hours are needed for reassembling and installation, and not much downtime is accompanied by maintenance work. These advantages make them trending building materials producing equipment currently.

3) The lower initial cost of buying a mobile concrete batching plant will benefit you so much that it can help you get what you deserve.

Details:

1. JS Concrete Mixer

1) Twin-shaft mixer is equipped with antomatic multi pumps lubrication system supplying grease to the four mixing shaft seals. There are virtually no grease distributor maintenance troubles, and working reliability is thus improved.

2) The gearbox, discharge pump, oil level and temperature at reducer, hydraulic door opening and anto lubrication system are all under monitoring, so as to ensure normal working status.

2. Metering System

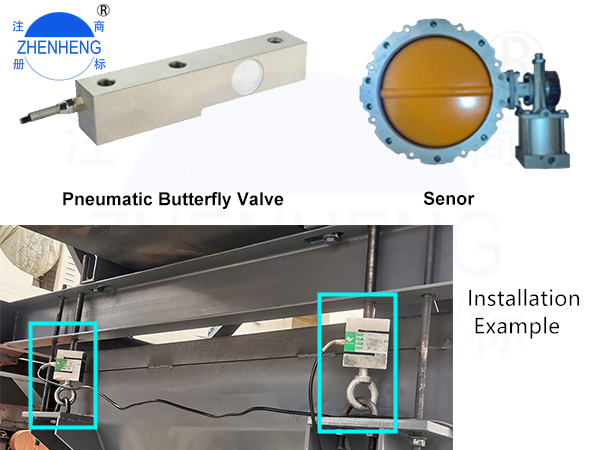

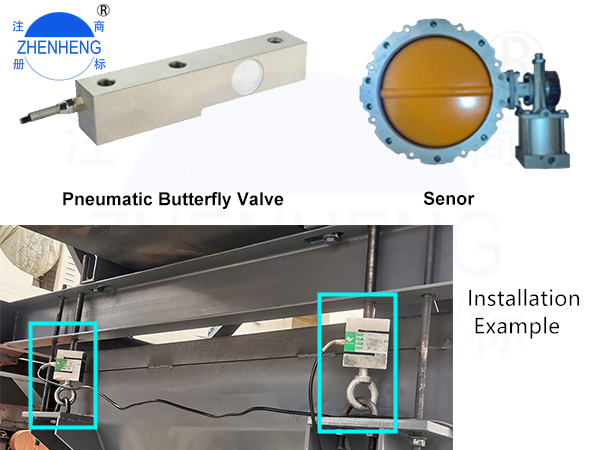

1) The sensor adopts high-precision imported sensor, accurate weighing and quick response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight and high in cost performance.

2. Metering System

1) The sensor adopts high-precision imported sensor, accurate weighing and quick response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight and high in cost performance.

3. Small Cement Hopper

The cement powder in 50kg/100kg type or jumbo bag type can be transferred to mixer through cement hopper and screw conveyor. There is a blade inside the cement hopper, which can damage the bag, drop the material into the bottom, and send it to the mixer by screw conveyor.

4. Belt Conveyor

1) High feeding and transportation efficiency

2) Improve production efficiency by more than 20%

4. Belt Conveyor

1) High feeding and transportation efficiency

2) Improve production efficiency by more than 20%

5. Fully Auto Control System

1) Self-developed dual-computer synchronous production management and control system, plus the patent of fault warning, multiple guarantees to make your equipment never stop;

2) Reports are automatically classified and summarized, and cloud data storage ensures clear data and convenient operation.

Parameters

|

Model |

YHZS35 |

|

Productivity |

35m3/hr |

|

Mixer Type |

JS750 |

|

Discharge Volume |

750L |

|

Aggregate Batch Machine |

5.5m3* 3bins |

|

Unloading Height |

3.8m |

|

Weighing Accuracy |

±1% |

|

Weighing System |

water, cement, additive |

|

Power |

65kw |

|

Control System |

Fully Auto |

|

Cement Silo |

50T |

|

Screw Conveyor |

LSY219*10 |